PRODUCTS

TC Replaceable Tip Drill

Catalog:

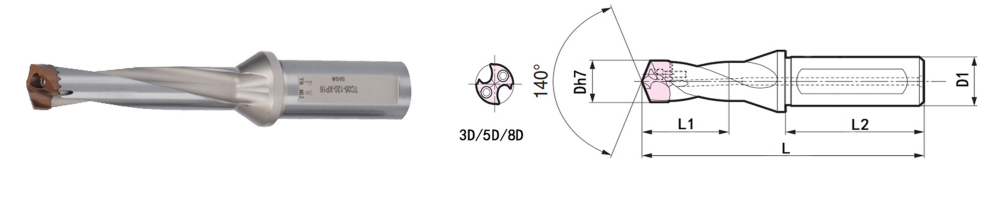

• Drill diameters are from 12mm to 32mm.

• Match with Mechin, Dormer and Sumitomo inserts.

• Various insert geometries for different materials.

• High strength alloy steel drill body.

• Double internal oil coolant holes.

• Weldon shank with flat.

• Drill radial runout less than 8um.

Hole tolerance: • 5D and less ratio: less than +0.02mm.

• 8D and larger ratio: less than +0.1mm.

keyword:Drilling,Boring

Detail

Highlights of Mechin Replaceable Tip Drill

★ Toothed occlusal structure with two screw fixing.

★ Various insert geometries optional.

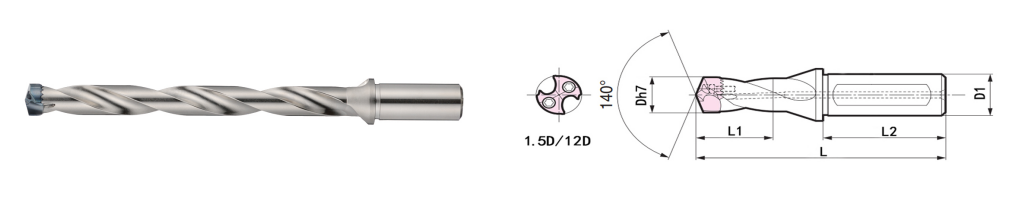

★ Up to 12 x diameter drilling depth.

★ Internal coolant with high strength alloy steel body.

★ Separate drill tip design with 140 degree.

Advantages of Mechin Replaceable Tip Drill

★ Much stable than other structure exchangeable tip drills.

★ Much higher precision against high speed drilling.

★ Higher rigidity and toughness against new holder material.

★ Stronger adaptability for different processing conditions.

★ Much lower costs under high efficient drilling than solid carbide drills.

Recommended Materials

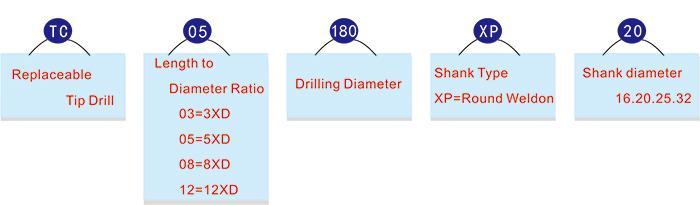

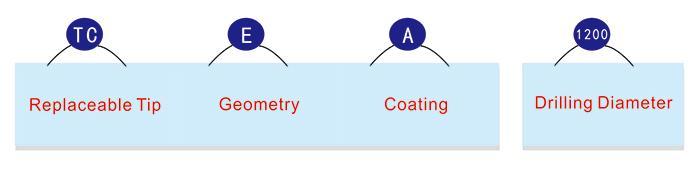

Product Naming of Replaceable Tip Drill and Inserts

Overall dimensions of Mechin TC Series Replaceable Tip Drills

| Diameter(D) | 3D | 5D | 8D | Shank Sizes | Screw | Key | |||||||

| Code | Sizes | Code | Sizes | Code | Sizes | Sizes | |||||||

| L1 | L | L1 | L | L1 | L | L2 | D1 | ||||||

| 12.0≤D<12.5 | TC03-120-XP16 | 46 | 107 | TC05-120-XP16 | 71 | 132 | - | - | - | 48 | 16 | M2.2*8 | T6 |

| 12.5≤D<13.0 | TC03-125-XP16 | 46 | 107 | TC05-125-XP16 | 71 | 132 | - | - | - | 48 | 16 | ||

| 13.0≤D<13.5 | TC03-130-XP16 | 49 | 112 | TC05-130-XP16 | 76 | 142 | - | - | - | 48 | 16 | ||

| 13.5≤D≤14.5 | TC03-140-XP16 | 55 | 119 | TC05-140-XP16 | 84 | 149 | TC08-140-XP16 | 127 | 194 | 48 | 16 | ||

| 14.5<D≤15.5 | TC03-150-XP20 | 58 | 129 | TC05-150-XP20 | 89 | 159 | TC08-150-XP20 | 136 | 204 | 50 | 20 | ||

| 15.5<D≤16.5 | TC03-160-XP20 | 62 | 134 | TC05-160-XP20 | 95 | 169 | TC08-160-XP20 | 144 | 214 | 50 | 20 | M2.5*9 | T8 |

| 16.5<D≤17.5 | TC03-170-XP20 | 66 | 140 | TC05-170-XP20 | 101 | 175 | TC08-170-XP20 | 154 | 225 | 50 | 20 | ||

| 17.5<D≤18.5 | TC03-180-XP20 | 70 | 145 | TC05-180-XP20 | 107 | 180 | TC08-180-XP20 | 162 | 230 | 50 | 20 | ||

| 18.5<D≤19.5 | TC03-190-XP25 | 73 | 160 | TC05-190-XP25 | 112 | 195 | TC08-190-XP25 | 171 | 255 | 56 | 25 | M3.0*11 | T8 |

| 19.5<D≤20.5 | TC03-200-XP25 | 77 | 160 | TC05-200-XP25 | 118 | 200 | TC08-200-XP25 | 179 | 270 | 56 | 25 | ||

| 20.5<D≤21.5 | TC03-210-XP25 | 80 | 160 | TC05-210-XP25 | 123 | 200 | TC08-210-XP25 | 188 | 266 | 56 | 25 | ||

| 21.5<D≤22.8 | TC03-220-XP25 | 84 | 165 | TC05-220-XP25 | 129 | 205 | TC08-220-XP25 | 196 | 275 | 56 | 25 | M3.5*12 | T15 |

| 22.8<D≤23.8 | TC03-230-XP25 | 81 | 165 | TC05-230-XP25 | 134 | 215 | TC08-230-XP25 | 205 | 285 | 56 | 25 | ||

| 23.8<D≤24.8 | TC03-240-XP32 | 91 | 175 | TC05-240-XP32 | 140 | 225 | TC08-240-XP32 | 213 | 300 | 60 | 32 | ||

| 24.8<D≤25.8 | TC03-250-XP32 | 93 | 175 | TC05-250-XP32 | 145 | 230 | TC08-250-XP32 | 222 | 305 | 60 | 32 | M4.0*14 | T15 |

| 25.8<D≤26.8 | TC03-260-XP32 | 97 | 180 | TC05-260-XP32 | 151 | 235 | TC08-260-XP32 | 230 | 315 | 60 | 32 | ||

| 26.8<D≤27.8 | TC03-270-XP32 | 99 | 180 | TC05-270-XP32 | 156 | 245 | TC08-270-XP32 | 239 | 325 | 60 | 32 | ||

| 27.8<D≤28.8 | TC03-280-XP32 | 102 | 185 | TC05-280-XP32 | 162 | 245 | TC08-280-XP32 | 247 | 330 | 60 | 32 | M4.5*15 | T15 |

| 28.8<D≤29.8 | TC03-290-XP32 | 105 | 190 | TC05-290-XP32 | 167 | 250 | TC08-290-XP32 | 256 | 340 | 60 | 32 | ||

| 29.8<D≤30.8 | TC03-300-XP32 | 110 | 191 | TC05-300-XP32 | 173 | 261 | TC08-300-XP32 | 265 | 351 | 60 | 32 | ||

| 30.8<D≤32.0 | TC03-320-XP32 | 116 | 201 | TC05-320-XP32 | 181 | 266 | TC08-320-XP32 | 276 | 361 | 60 | 32 | ||

| 32.0<D≤33.5 | TC03-335-XP32 | 121 | 206 | TC05-335-XP32 | 191 | 276 | TC08-335-XP32 | 291 | 376 | 60 | 32 | ||

| 33.5<D≤35.0 | TC03-350-XP32 | 126 | 221 | TC05-350-XP32 | 201 | 296 | TC08-350-XP32 | 306 | 401 | 70 | 40 | M5*15 | T20 |

| 35.0<D≤36.5 | TC03-365-XP32 | 132 | 227 | TC05-365-XP32 | 207 | 302 | TC08-365-XP32 | 317 | 412 | 70 | 40 | ||

| 36.5<D≤38.0 | TC03-380-XP32 | 137 | 232 | TC05-380-XP32 | 217 | 312 | TC08-380-XP32 | 332 | 427 | 70 | 40 | ||

| 38.0<D≤39.5 | TC03-395-XP32 | 142 | 237 | TC05-395-XP32 | 227 | 322 | TC08-395-XP32 | 342 | 437 | 70 | 40 | ||

| 39.5<D≤41.0 | TC03-410-XP32 | 152 | 252 | TC05-410-XP32 | 232 | 332 | TC08-410-XP32 | 357 | 457 | 70 | 40 | ||

| 41.0<D≤42.5 | TC03-425-XP32 | 158 | 258 | TC05-425-XP32 | 243 | 343 | TC08-425-XP32 | 368 | 468 | 70 | 40 | ||

| Diameter(D) | 1.5D | 12D | Shank Sizes | Screw | Key | |||||

| Code | Sizes | Code | Sizes | Sizes | ||||||

| L1 | L | L1 | L | L2 | D1 | |||||

| 12.0≤D<12.5 | TC1.5-120-XP16 | 28 | 91 | - | - | - | 48 | 16 | M2.2*8 | T6 |

| 12.5≤D<13.0 | TC1.5-125-XP16 | 28 | 91 | - | - | - | 48 | 16 | ||

| 13.0≤D<13.5 | TC1.5-130-XP16 | 30 | 92 | - | - | - | 48 | 16 | ||

| 13.5≤D≤14.5 | TC1.5-140-XP16 | 34 | 96 | TC12-140-XP16 | 171 | 239 | 48 | 16 | ||

| 14.5<D≤15.5 | TC1.5-150-XP20 | 35 | 100 | TC12-150-XP20 | 183 | 253 | 50 | 20 | ||

| 15.5<D≤16.5 | TC1.5-160-XP20 | 38 | 103 | TC12-160-XP20 | 195 | 266 | 50 | 20 | M2.5*9 | T8 |

| 16.5<D≤17.5 | TC1.5-170-XP20 | 39 | 105 | TC12-170-XP20 | 207 | 278 | 50 | 20 | ||

| 17.5<D≤18.5 | TC1.5-180-XP20 | 43 | 107 | TC12-180-XP20 | 219 | 291 | 50 | 20 | ||

| 18.5<D≤19.5 | TC1.5-190-XP25 | 44 | 115 | TC12-190-XP25 | 232 | 309 | 56 | 25 | M3.0*11 | T8 |

| 19.5<D≤20.5 | TC1.5-200-XP25 | 47 | 118 | TC12-200-XP25 | 244 | 321 | 56 | 25 | ||

| 20.5<D≤21.5 | TC1.5-210-XP25 | 48 | 119 | TC12-210-XP25 | 256 | 334 | 56 | 25 | ||

| 21.5<D≤22.8 | TC1.5-220-XP25 | 51 | 121 | TC12-220-XP25 | 268 | 347 | 56 | 25 | M3.5*12 | T15 |

| 22.8<D≤23.8 | TC1.5-230-XP25 | 51 | 122 | TC12-230-XP25 | 280 | 359 | 56 | 25 | ||

| 23.8<D≤24.8 | TC1.5-240-XP32 | 54 | 129 | TC12-240-XP32 | 292 | 376 | 60 | 32 | ||

| 24.8<D≤25.8 | TC1.5-250-XP32 | 54 | 129 | TC12-250-XP32 | 305 | 388 | 60 | 32 | M4.0*14 | T15 |

| 25.8<D≤26.8 | TC1.5-260-XP32 | 57 | 132 | - | - | - | 60 | 32 | ||

| 26.8<D≤27.8 | TC1.5-270-XP32 | 58 | 133 | - | - | - | 60 | 32 | ||

| 27.8<D≤28.8 | TC1.5-280-XP32 | 60 | 135 | - | - | - | 60 | 32 | M4.5*15 | T15 |

| 28.8<D≤29.8 | TC1.5-290-XP32 | 61 | 136 | - | - | - | 60 | 32 | ||

| 29.8<D≤30.8 | TC1.5-300-XP32 | 64 | 139 | - | - | - | 60 | 32 | ||

| Diameter D(mm) | Code | L(mm) | Code | L(mm) | |

| 12.0 | TCEA-1200 | TCPA-1200 | 9.1 | TCFA-1200 | 7.1 |

| 12.5 | TCEA-1250 | TCPA-1250 | 9.4 | TCFA-1250 | 7.2 |

| 13.0 | TCEA-1300 | TCPA-1300 | 9.7 | TCFA-1300 | 7.5 |

| 13.5 | TCEA-1350 | TCPA-1350 | 10.3 | TCFA-1350 | 7.9 |

| 14.0 | TCEA-1400 | TCPA-1400 | TCFA-1400 | ||

| 14.5 | TCEA-1450 | TCPA-1450 | TCFA-1450 | ||

| 15.0 | TCEA-1500 | TCPA-1500 | 11.0 | TCFA-1500 | 8.3 |

| 15.5 | TCEA-1550 | TCPA-1550 | TCFA-1550 | ||

| 16.0 | TCEA-1600 | TCPA-1600 | 11.6 | TCFA-1600 | 8.8 |

| 16.5 | TCEA-1650 | TCPA-1650 | TCFA-1650 | ||

| 17.0 | TCEA-1700 | TCPA-1700 | 12.3 | TCFA-1700 | 9.3 |

| 17.5 | TCEA-1750 | TCPA-1750 | TCFA-1750 | ||

| 18.0 | TCEA-1800 | TCPA-1800 | 12.9 | TCFA-1800 | 9.8 |

| 18.5 | TCEA-1850 | TCPA-1850 | TCFA-1850 | ||

| 19.0 | TCEA-1900 | TCPA-1900 | 13.6 | TCFA-1900 | 10.2 |

| 19.5 | TCEA-1950 | TCPA-1950 | TCFA-1950 | ||

| 20.0 | TCEA-2000 | TCPA-2000 | 14.1 | TCFA-2000 | 10.7 |

| 20.5 | TCEA-2050 | TCPA-2050 | TCFA-2050 | ||

| 21.0 | TCEA-2100 | TCPA-2100 | 14.8 | TCFA-2100 | 11.2 |

| 21.5 | TCEA-2150 | TCPA-2150 | TCFA-2150 | ||

| 22.0 | TCEA-2200 | TCPA-2200 | 15.0 | TCFA-2200 | |

| 22.5 | TCEA-2250 | TCPA-2250 | TCFA-2250 | ||

| 23.0 | TCEA-2300 | TCPA-2300 | 15.2 | TCFA-2300 | |

| 23.5 | TCEA-2350 | TCPA-2350 | TCEA-2350 | ||

| 24.0 | TCEA-2400 | TCPA-2400 | 15.4 | TCFA-2400 | 11.3 |

| 24.5 | TCEA-2450 | TCPA-2450 | TCFA-2450 | ||

| 25.0 | TCEA-2500 | TCPA-2500 | 15.9 | TCFA-2500 | 11.7 |

| 25.5 | TCEA-2550 | TCPA-2550 | TCFA-2550 | ||

| 26.0 | TCEA-2600 | TCPA-2600 | 16.5 | TCFA-2600 | 12.2 |

| 26.5 | TCEA-2650 | TCPA-2650 | TCFA-2650 | ||

| 27.0 | TCEA-2700 | TCPA-2700 | 17.2 | TCFA-2700 | 12.7 |

| 27.5 | TCEA-2750 | TCPA-2750 | TCFA-2750 | ||

| 28.0 | TCEA-2800 | TCPA-2800 | 17.8 | TCFA-2800 | 13.2 |

| 28.5 | TCEA-2850 | TCPA-2850 | TCFA-2850 | ||

| 29.0 | TCEA-2900 | TCPA-2900 | 18.4 | TCFA-2900 | 13.6 |

| 29.5 | TCEA-2950 | TCPA-2950 | TCFA-2950 | ||

| 30.0 | TCEA-3000 | TCPA-3000 | 19.0 | TCFA-3000 | 14.1 |

| 30.5 | TCEA-3050 | TCPA-3050 | TCFA-3050 | ||

| 31.0 | TCEA-3100 | TCPA-3100 | 21.0 | - | - |

| 31.5 | TCEA-3150 | TCPA-3150 | - | - | |

| 32.0 | TCEA-3200 | TCPA-3200 | - | - | |

TCEA geometry is suitable for stainless steel, soft steel, gray cast iron, and low rigidity setups.

TCPA geometry is suitable for general steel.

TCMA geometry is suitable for general steel.

TCFA geometry is suitable for drilling non-flat surface.

Messages

If you are interested in our products, please leave us a message and we will contact you as soon as possible!